Since so many projects that I consider call for wheels,

and since I knew and stated that I was not very accomplished at building them,

I decided to conduct some serious experimenting and learn how to build a good and true wheel.

In the past I had used flat stock made round on the anvil horn. It resulted in a good circular form.

The hubs that I've built were also good.

But when I put the round and the hub together with spokes, things got off center and askew so that the wheel bounced and wobbled.

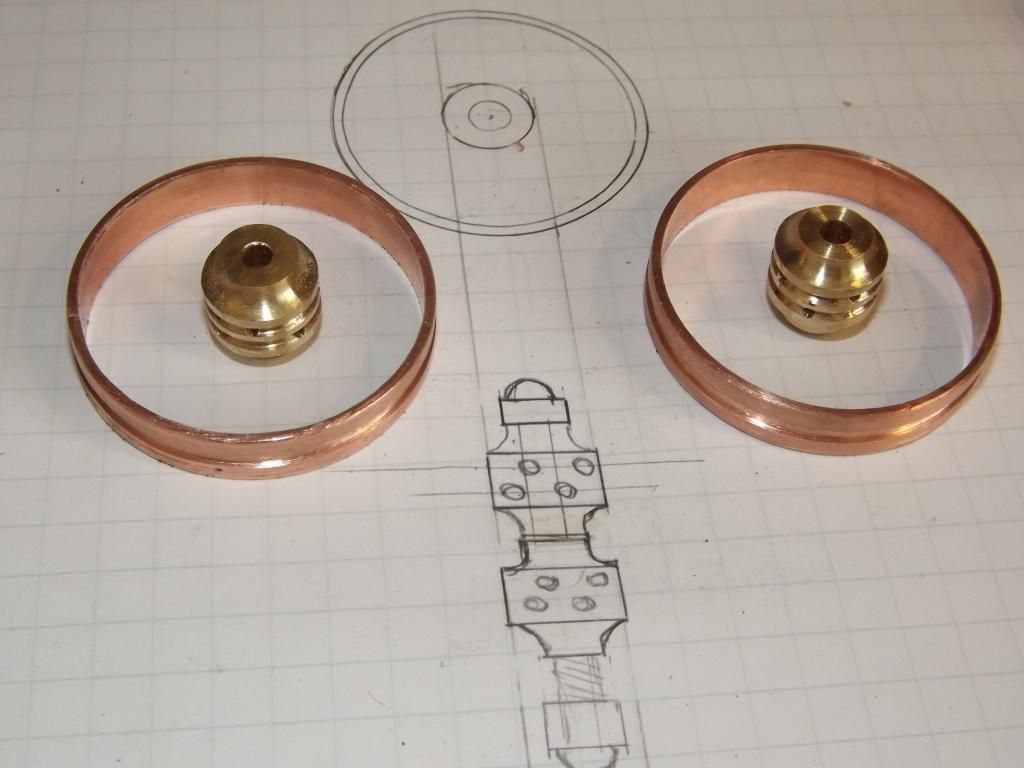

This time I decided to cut rims from brass plumbing pipe:

Then I turned the hubs, measured carefully, marked equal spacing and drilled holes to match on the rim and hub employing tooth picks for alignment

.

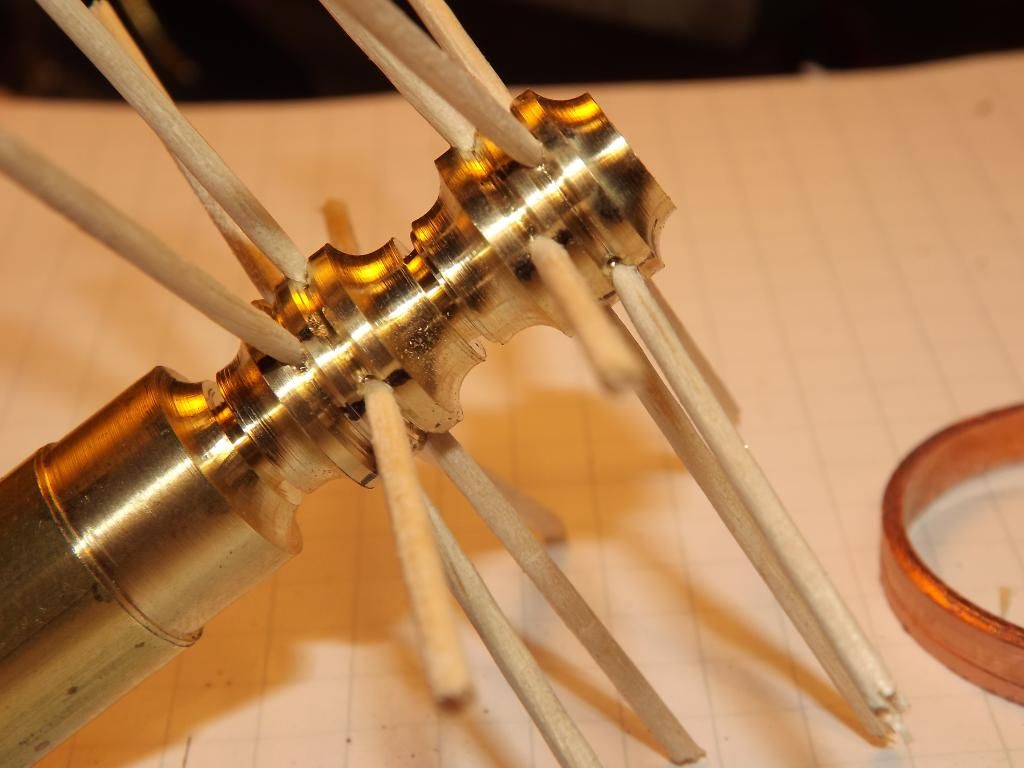

Then to ensure that all the parts were true and level devised an apparatus for assembly:

And inserted spokes true to the rim and the hub:

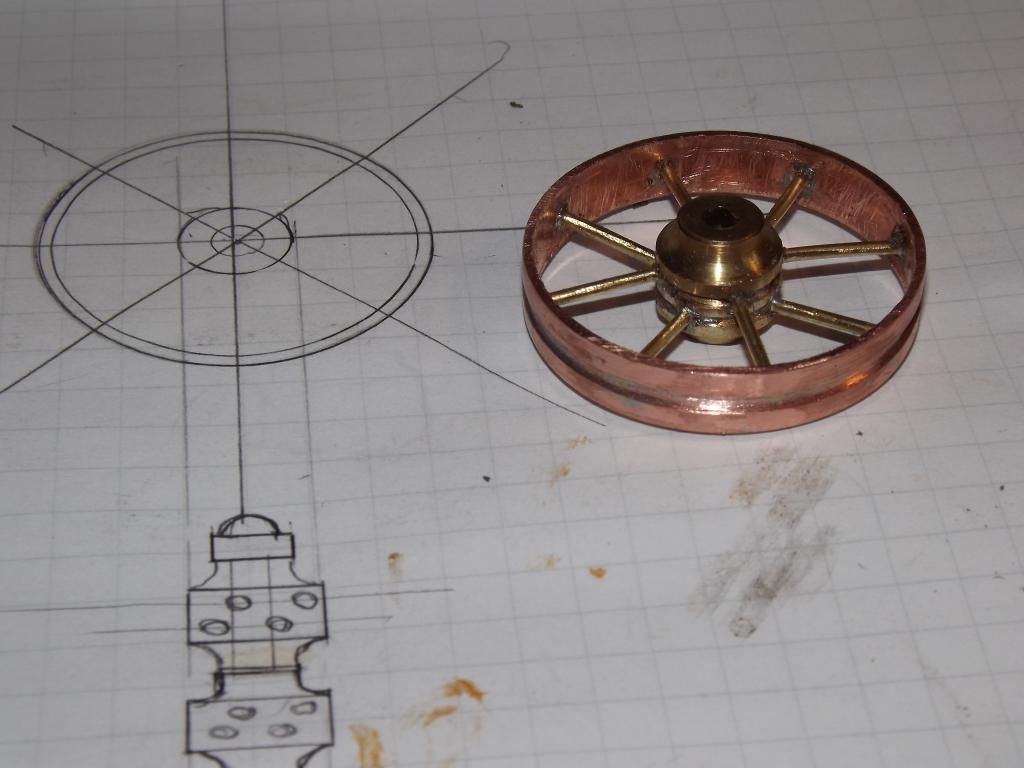

And a nice true - balanced wheel resulted:

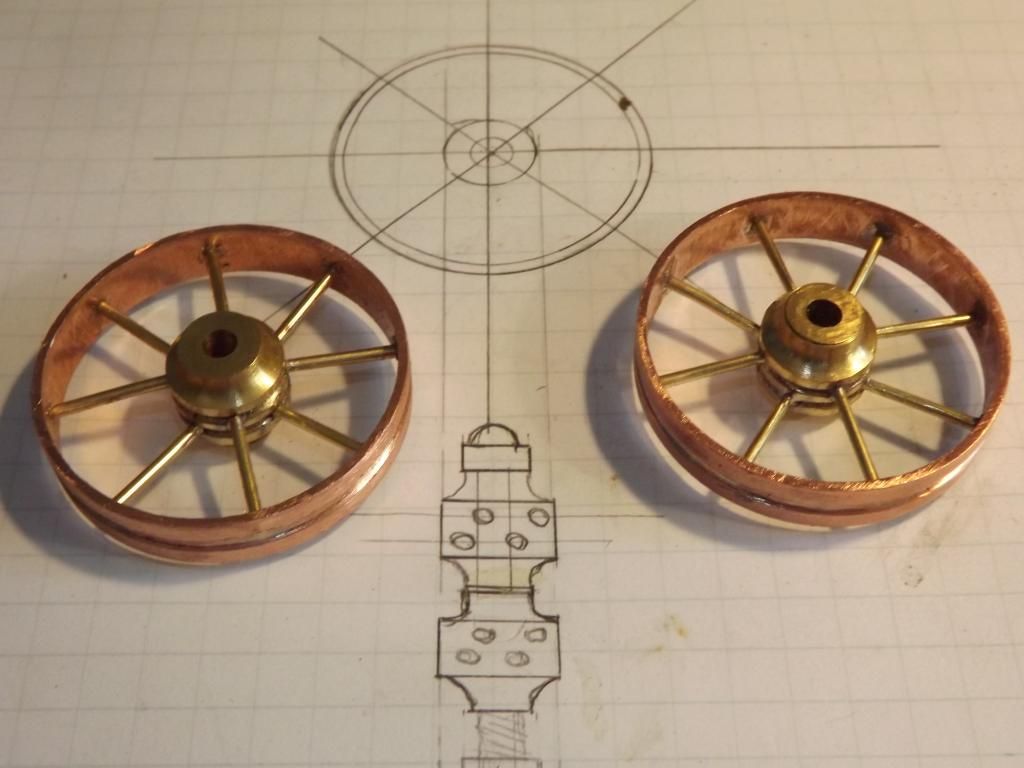

So I did it again. And now there are two built to resemble old style type implement wheels.

Two more and I can build a four wheeler of some sort.

I didn't intend to make such a big deal of it all since building wheels must be one of the oldest crafts in the history of mankind.

But it was a nagging shortcoming of mine that I had to overcome once and for all.

I may in the future discover better methods and instrumentation, and I'm open to all ideas,

since I know that there must be more than one way to build a wheel. Ralph