Several weeks ago I took a picture of a large pipe elbow for comment. In that picture there was a treasure in the background that I wasn't aware was there. I believe it was John's keen eye that honed in on the press from there. It was a rather old drill press mounted to a piece of large C-channel laying face down in the dirt.

I had time today to move the things required to get a tractor over that way and pick it up. This is what I lifted once I was able to get to it.

It is date stamped 12/21/1915 - Patent 116535

This is a view with the c-channel removed and a power washing.

This is the worst of the worst damage:

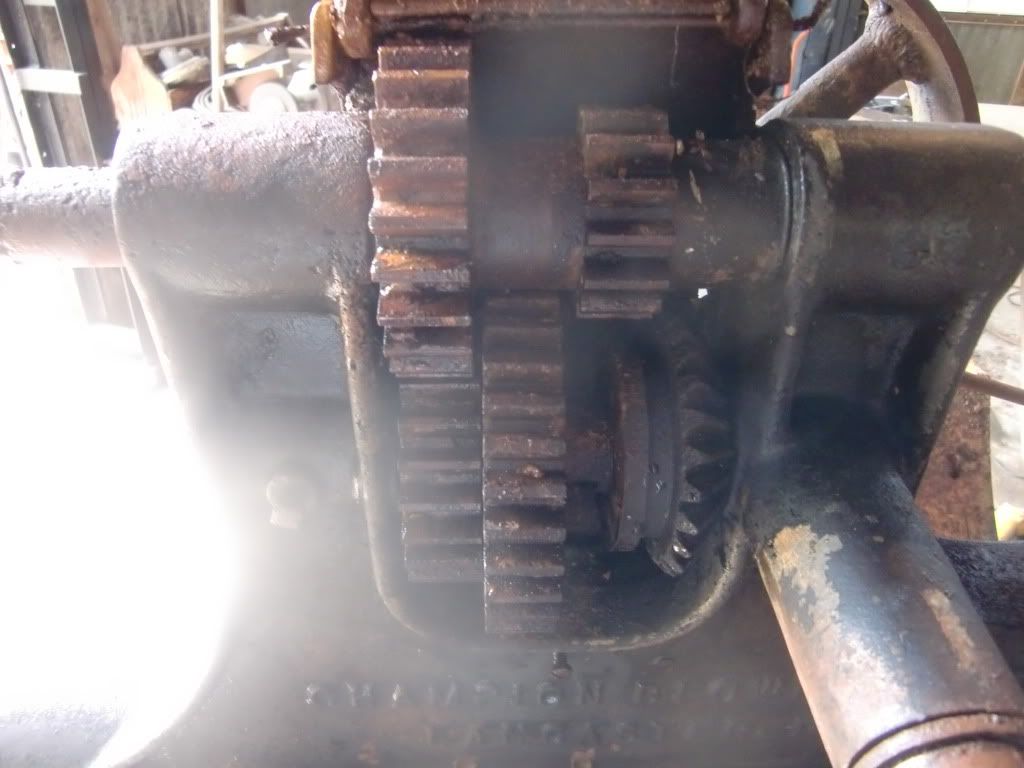

A very sweet Low/High speed gear setup - change it with a slide of the gear.

I do not understand this part of the press - it would be located at the top opposite the lift/lower handle side.

Oh just great - another wrench to look for

and this is her after the first good cleaning, and a little oiling. Everything did free up and moves very well by hand.

What's next? Before I decide I would like to hear feedback on the pros, cons, benefits, etc. of repairing versus not repairing the rusted/pitted area on the shaft closest to the bit. All of the shaft that makes contact with a seal or wiper looks great. I just don't have the experience with a keyless chuck? to say if there is a consequence of not repairing that area. I'd appreciate any feedback you may have.