This is a weavers reed hook. In particular it's my Dad's reed hook when he was a weaver in Lincoln Mills in the middle '30's. It was also my reed hook when I was a loom fixer in Huntsville Manufacturing in the '70's.

A much older loom but run on the same principles as the 1898 looms I ran except ours had 4 harnesses instead of 2.

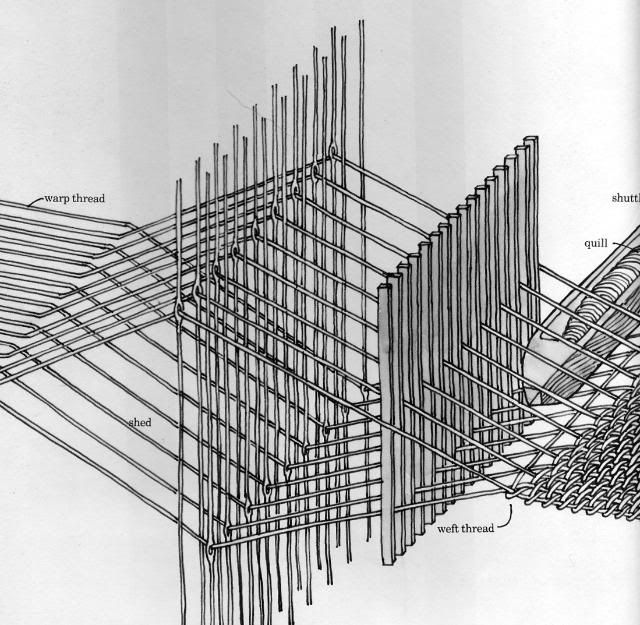

In the upper right is the shuttle. It is running in the shed and in that position is going over 100 miles an hour and is traveling on the lathe. The vertical bars behind the shuttle is the reed. When the shuttle has boxed, the lathe will come forward against the thread just laid down and pack it tight in the warp threads. The harness will shift, so that the threads that were up, are now down and down is now up and the shuttle goes the other way. The loom does this about 88 times a minute. When a thread breaks the loom stops and the weaver/loom fixer/tie in will tie in a new thread in a weavers knot (like a surgeons knot) ,clip off the ends and using the reed hook pull the new thread through the right harness slot and the right reed slot and tie to the broken thread. Then restart the loom.