Hi, Frank. It is nice to have family visit, and since I live at the base of Pikes Peak near The Garden of the Gods, etc., my house is a likely place for guests.

But I like my alone time and got right back to it and made some progress yesterday.

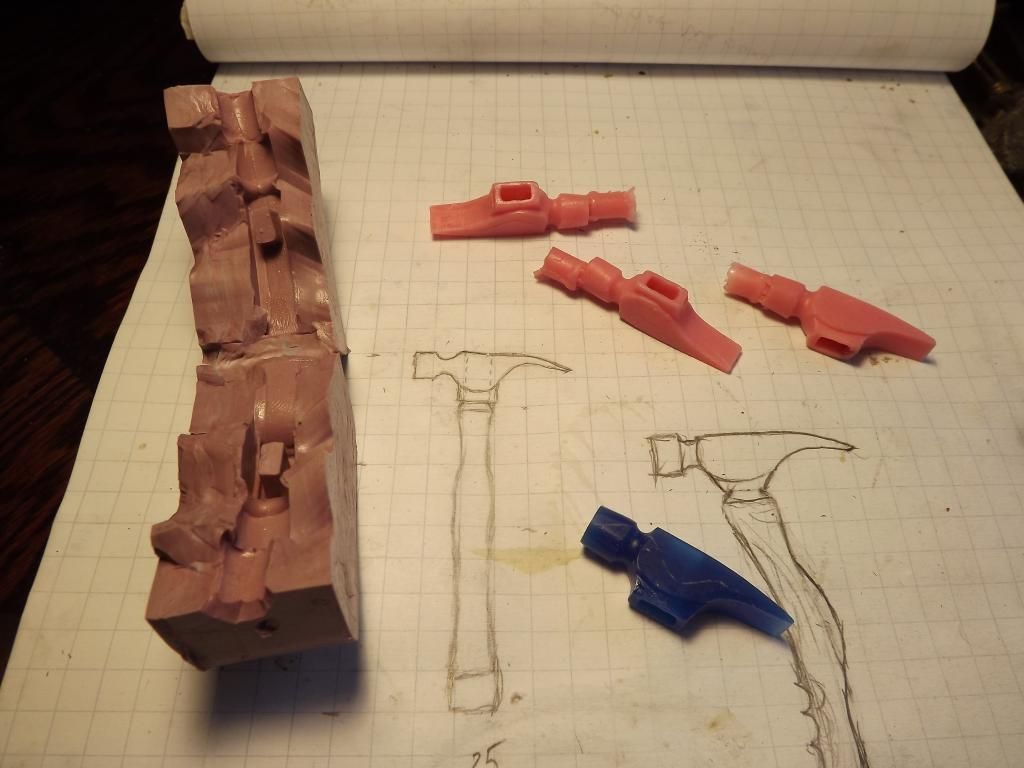

Chilly had suggested that I try a "new" to me mold making procedure - Silicone.

I am most familiar with rubber molds having built scores of rubber molds - the hard way,

cutting strips, packing around a metal model in a solid frame and vulcanizing it under pressure in an oven.

This procedure requires that a metal master pattern first be made / cast from an original carved wax model, etc. etc. etc..

I have posted an account of that procedure further up this string.

This "new" procedure spares several laborious steps

and did yield good results with half the work in much less time

since I could encapsulate an original wax model in silicone

then just cut it open with no heat vulcanizing.

Hot wax was injected directly into the mold to produce exact soft wax copies for casting. Ralph

Next plaster molds will be created for casting the final pieces.

Two hammers were requested, but I always like to build an extra piece for a commission in case something goes wrong.

And if all works out OK, the extra piece is for my collection.