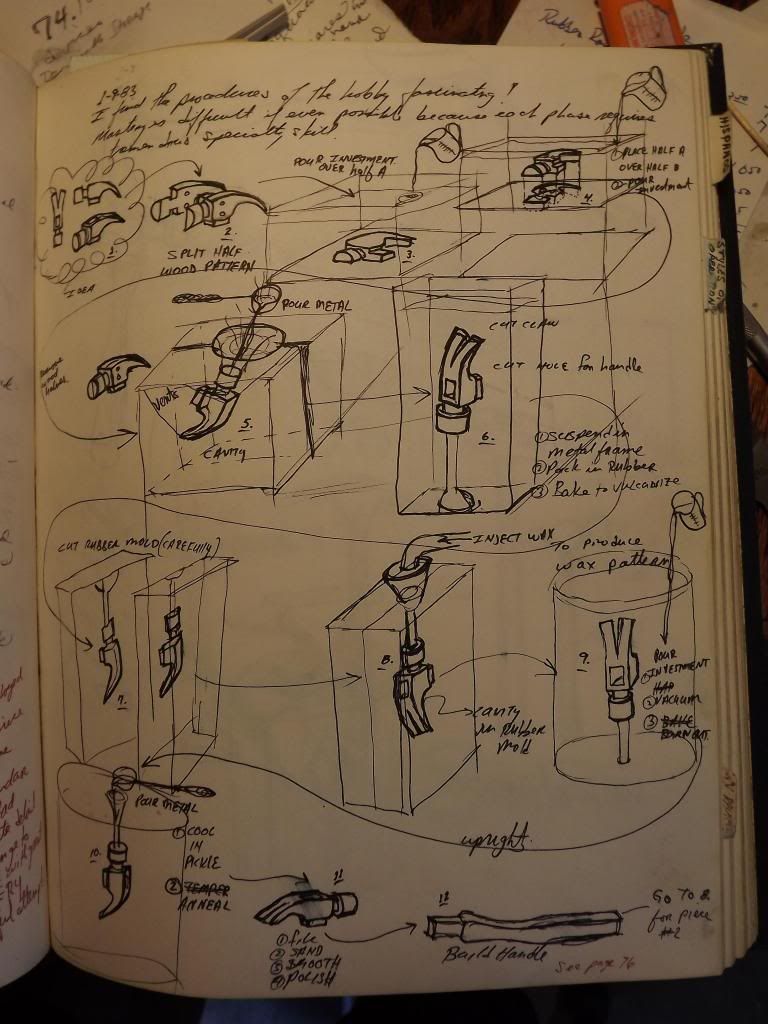

Hi John. Yes I make all my own silver and gold castings (although not so much gold these days). My brass stuff is primarily fashioned and fabricated from flat stock -- cut out, arranged (posed) and silver soldered. I have used the "split half" - cope and drag sand casting process. And and split half plaster mold casting. And "lost wax" casting employing a centrifuge, which I prefer for casting higher quality more detailed pieces. Posted below is a simply sketched example of a "split half" process I have used. The "lost wax" process is a little more complex but basically similar. Ralph

In the lost wax process a wax model is carved - fashioned from a bar - piece of wax, and it is suspended in a container (flask) into which investment ( plaster ) is poared and allowed to harden under high heat which melts the wax out (lost wax) leaving a cavity in the shape of the model in the plaster into which molten metal is poared. The plaster is then broken off revealing the solid metal piece ready for fileing, sanding, polishing and general finishing. Or something like that. I could describe the process better in volumes, but it's hard to do in a few words. Ralph