Progress steams right along...

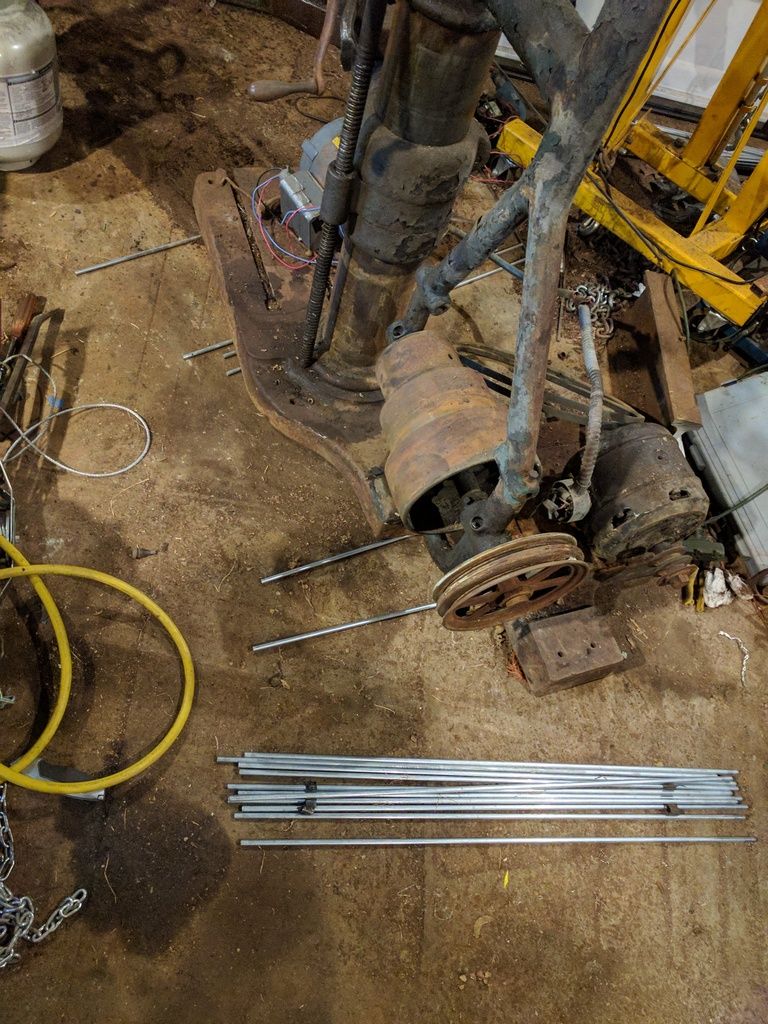

I really love the lines on this press... It looks like how H.R. Geiger would design a drill press. (I'm mostly looking at the curved part that comes up over the top on that one, it very much resembles a Xenomorph from Alien) I really want to sit and paint the thing... but that's time and expense I don't have right now.

I managed to move the thing across my shop by lifting it on top of some lengths of 3/8" round stock, and just pushing it. This would be much easier if my garage floor were smooth, but unfortunately my uncle didn't take the time to do a nice job when he put it in 30 years ago... oh well, at least it isn't cracked...

As it turns out, McMaster Car is also from Minnesota, so my belt showed up this morning after only one business day... I had a little trouble installing the alligator, the back side kept wanting to twist rather than to dig into the belt. But after some fiddling with a pair of needle nose pliers, and using my blacksmith vise instead of a hammer, I got the lacing in and the belt on. (Yes, my shop is a horrible nightmare of a mess... it's constantly changing and evolving... I'm working on organizing it ^^;)

I drilled, and tapped the broken handle. Inserting a 1/4" machine screw, and JB ClearWelded the two parts back together, as well as the screw. Supposedly the Clearweld has a 4,400PSI yield strength, (Which is 500 greater than regular JB) combined with the screw, I'm hoping this will make for a sufficient repair.

As it turns out... my friend has a similar-era W.F.&J. Barne's drill press laying in his yard, though this one has the moveable head. Unfortunately, he is unwilling to sell me parts for mine... but his does have some stickers which shed light on the funny perforated wheel with the adjustable post. This adjusts the feed-speed of the auto-feed.

I'm just waiting on the capacitor for my new 3HP 3ph motor to build my 3 phase converter, and some new v-belts to link the motor to the flat belts. Both of which should be here before the end of the week, so I should have her up and running this weekend at the latest, assuming both motors work! Though, I have a known good 3/4HP 3ph already I'll swap out with the included motor if it doesn't run.