That motor looks old enough to have a brass plate on one of the end bell, maybe the pulley side? Ican't seem to find pics of mine on the computer. I'm sure there are pics on my shop page in FB. 3000 pics there probably 10-20 of it on there.

I think I found a plaque on the motor, but it's completely obscured at the moment... I'll try to carefully clean it, but it might be painted over, a little hard to tell, I have to get the rest of the "Safety" cage off of it before I can get to it.

Anywho, futzed about with it as I said I would today, and have goods, and bads, and apparently I was exagerating on the number of levers :P

It is a W. F. & J Barne's 25" drill press, which is larger than any of the ones posted on Vintage machinery. None of their catalogues seem to have it listed either, but the only metal working machinery catalogue they have up is from 1898, since this was made specifically with an electric motor, it's almost certainly more modern than that. I believe I found a plaque with more details on it, but it's been painted over heavily, and will take some care to clean and read.

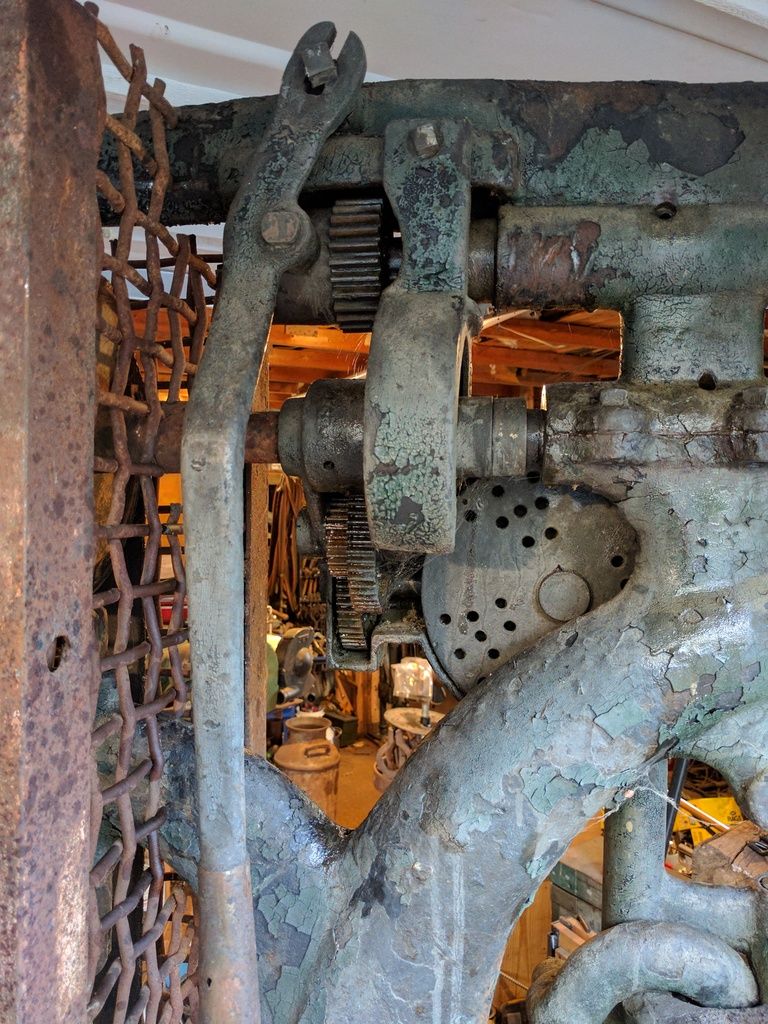

The press has two driveshafts, which can be switched with the large lever on the left side of the press nearest the belt drive. The upper shaft appears to run on gear reduction, while the lower shaft is direct drive. The lever in the head, from which the quill descends, allows you to switch between the upper and lower shafts. However, the gear has been welded/brazed to the lower drive :/ It looks as though the teeth were somewhat stripped, and someone just went ahead and solved it brute force. I'd love to replace the two surfaces and get it working again, but I doubt I'll come across parts any time soon...

Over on the right, are all the parts I previously mentioned... Main crank down, a worm-gear hand crank, and the switch that activates the auto-feed... Reading some of the catalogues leads me to think that the press might have an auto-stop as well, but I don't see what mechanism would allow that... Maybe whatever the chain on the quill hooks to inside the frame?

Also on the right, there's a strange slot with a post, and 4 locking holes... on the other side, there is a wheel with many holes drilled through it. I have no idea what this is for... I didn't fiddle with it extensively yet though...

Someone appears to have just put in new babbit into the bearings, which is awesome. But, they forgot to drill back out the oil-holes. Which is bad, but easily fixed, just have to pull the drive shafts and drill them out.

Table height adjustment works remarkably well... Taking a wire-wheel to the shaft quickly should make it adjust smooth as silk...

In my wrestling with it the other day, I broke the lever that engages the worm-gear feed... any suggestions on reattaching it? ^^;